ASTRO-PHYSICS

10" F14.6 High-Resolution Maksutov-Cassegrain

10" Mak under test in our roll-off roof observatory.

Note the small secondary obstruction.

10" Mak under test in our roll-off roof observatory. Note the small secondary obstruction. |

This telescope was developed for those desiring a no-compromise high-power instrument for all visual and imaging needs. Ideal for lunar/planetary, double star and high-resolution deep-sky observing.

Advanced Optical Design

The heart of this Maksutov is a special variation of the Gregory design using an elliptical primary and low-power corrector to achieve the lowest possible central obstruction, yet still maintain a reasonable focal ratio. The optics were designed by Valery Deryuzhin of Aries Instrument Company in the Ukraine. The design is coma-free and totally diffraction-limited from deep infrared right into the ultraviolet - a perfect match for todayís premium CCD chips. The small obstruction results in a telescope that shrugs off poor seeing as if it were a refractor, delivering high-contrast performance with super-tight star images.

Thermally Stable

From years of experimenting with 8" and 10" prototypes, we have found very effective ways to rapidly cool down the optics for stable high-power viewing. We have been testing this 10" design for almost a year now in all kinds of weather from warm summer nights to bitter cold winter conditions with rapidly falling temperatures. With its fused silica primary, the figure is remarkably stable even when the optics are still cooling down to the ambient temperature. To minimize thermal gradients and help the mirror shed its heat, we designed a special mirror cell assembly. Cool night air can flow across the back of the mirror. To further speed up the cooling process in the most extreme conditions, we have added two small fans, which can be run at full speed, or at a slow whisper quiet speed. The air blows directly at the back of the mirror - no air goes inside the tube and cannot cause particulate contamination of the mirror surfaces.

The mirror is a truncated cone to eliminate as much thermal mass as possible. The back of the mirror is fine ground and polished, which helps internal trapped heat to radiate out the open back. By grinding the edge and back, tiny stresses are relieved which could otherwise introduce unwanted distortions in the highly accurate front surface at different ambient temperatures. In side-by-side tests against closed back scopes with conventional molded mirrors, our design was faster, by far, in achieving a stable, accurate image.

Central Obstruction

Much has been written pro and con about the need for a small central obstruction. While the light loss of a secondary obstruction is quite small, even in a large obstruction, undesirable diffraction effects are in direct proportion to the obstruction size. Our observations over more than 20 years with all kinds of optical systems have convinced us of the desirability of small obstructions for visual systems. Commercial "fast food" catadioptrics have obstructions between 35% to 40% (and this includes some

High power image of Vega taken with 10" Mak using an Olympus DL600 digital camera. Seeing was 7 out of 10. Shown is Airy disc and first diffraction ring. |

Any optical imperfections, such as surface roughness and zonal errors on the mirrors, adds to the problem. We tested a commercial scope where the central obstruction, optical errors and surface roughness were large enough to cause the first diffraction ring and central Airy disc to have almost equal brightness (with a 35% obstruction, theoretically there should be at least a 4 to 1 difference). Even so, this scope "tested" very well on the star test - it had quite similar inside and outside Fresnel patterns and might be judged textbook perfect by the star test. Yet it was a very poor performer on all but the most steady of nights, when the seeing was essentially perfect. The slightest motion in the atmosphere would cause cotton ball stars. This is one reason I have not been a major fan of the "star test" to evaluate the actual performance of a telescope. The only unbiased way to measure an optic is with interferometry, with an MTF (modulation transfer function) test, or with a PSF (point spread function) test, which measures the relative strength of the Airy disc vs. the diffraction rings with the image IN FOCUS.

Optical Quality

The 10" Mak-Cass optics are fabricated by skilled opticians of the Aries

Instrument Company in the Ukraine, in close co-operation with the Crimean Astrophysical

Observatory. The optics are hand figured to 1/10 wave P-V using a green light

interferometer in double-pass mode. We supply the precision-annealed blanks

of Corning fused silica for the mirrors, and solid blanks of high-quality Ohara

BK7 for the correctors. That way, there is no question of internal homogeneity,

striae or strain. They are expensive, but they free the optician to concentrate

on making very accurate and smooth curves on the optical surfaces without having

to compensate for local discontinuities in the glass, or worrying about the

mirror warping during polishing. Fused silica was chosen both for its high stability

during polishing and figuring, and for its thermal performance under actual

night-sky conditions. The end result is an optical system that does what itís

supposed to do - produce unparalleled views of the planets and deep-sky objects.

Mechanical Design and Execution

Our tube assemblies were designed right from the start with trouble-free precision

as the major goal. This means that collimation is set at the factory and does

not change for the life of the instrument. To achieve this, all optics are accurately

centered, including the mirror backs. All mounting components are made from

solid billets - no fragile die castings anywhere! The critical mirror cell starts

out as a solid 12" diameter aluminum slug weighing in excess of 30 lb.

It is then precisely machined to very tight tolerances on our Mori-Seiki SL300

turning center. The finished mirror cell with its ventilation cutouts weighs

a mere 2 lb. The other 28 lb. in the form of chips is, of course, recycled.

Similar care is taken with the corrector cell and other mounting components.

The result is a scope you can count on to produce consistently excellent images

any time, any place. Focuser Design We opted for a moving mirror focuser to accommodate a wide variety of photographic

and visual accessories. The goal was to achieve precise movement of the mirror

down to the micron level with no image shift. To accomplish this, we designed

a pre-loaded axial ball bearing assembly with a precision screw thread, which

moves the mirror on its centerline, not off-axis as is done in the majority

of commercial catadioptrics. With this system, your image will stay on that

tiny CCD chip regardless of focuser position. You wonít have to install an aftermarket

Crayford focuser for your critical applications. Best of all, the mirror maintains

its collimation and wonít flop around as you go from one part of the sky to

the other. No need to tie the mirror down with external bolts to keep it from

shifting during a time exposure. Major Features: Specifications Clear aperture

10 inches, 254mm

Secondary size

2.3 inches, 23%

Focal length

146 inches, 3708mm

Focus range

9.5 inches, 241mm

Focal ratio

f14.6 nominal, f13.6 at min focus, f15.8 at max focus point

Field size

3/4 degree (1.5 moon diameters), over a 2 inch field

Magnification range

62x with 60mm ocular to 927x with 4mm ocular

Resolution

0.45 arc seconds

Size

12" diameter x 26" long

Weight

33 lb., 15kg.

Finish

Black anodized cells, white textured tube

Mirror coating

96% enhanced and protected aluminum

Corrector coating

Broadband multi-coatings both sides

Mirror cell being machined on the

Mori Seiki turning center

Price:

$9,800.00 USD

Digital Images

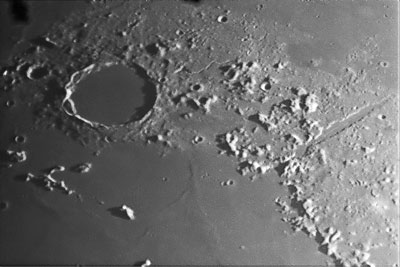

These are some of the first images taken in December with the 10" Mak using a Starlight Express HX516 Camera. Images by R. Christen.

|

|

|

|

Copyright

© 2002, Astro-Physics, Inc. - All Rights Reserved

This page was last modified: May 1, 2002

Astro-Physics,

Inc.

11250 Forest Hills Road, Rockford, IL 61115, U.S.A.

Phone: 815-282-1513 Fax: 815-282-9847